What is impact test for pipe fitting?

Charpy impact test principle:

Charpy impact test is to place the pipe fittings’ sample with the specified shape,size and notch type on the sample holder of the impact tester so that it is in the state of simply supported beam.Then one-time strike the pipe fittings’ sample with a pendulum of a prescribed height,which is essentially the energy conversion process that measures the work absorbed when the sample breaks under such an impact.Impact test is to test the notch toughness of pipe fittings’ material and study temperature-dependent ductile-brittle transition.

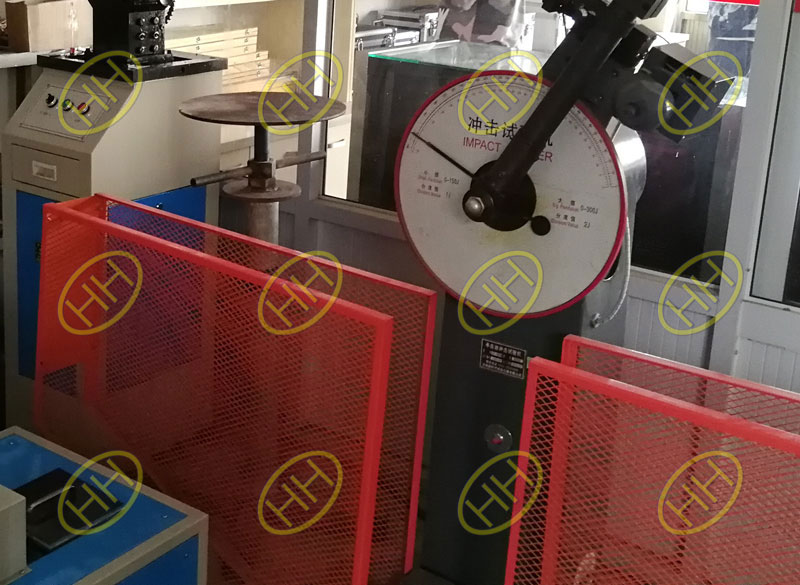

Impact test in Haihao Group

Low temperature impact test means impact tests below 10 celsius degrees.

In the low-temperature impact test,the pipe fittings’ sample should be kept at the specified temperature for a sufficient time so that the entire sample can reach the specified uniform temperature. If using liquid medium, the holding time should not be less than 5min; when using gaseous medium, the holding time should be no less than 20min. At the same time, the jig used to remove the sample should also be placed in a cooling medium at the same temperature to ensure that it is substantially the same temperature as the medium.

Haihao Group can manufacture all types pipe fittings and flanges in high quality,we has non-destructive testing apparatus,supersonic testing apparatus, universal testing machine,impact test machine and physical & chemical labs,forming a complete quality assurance system.At the same time,well-trained specialists master the perfect detecting means,achieving a conformity rate of 100% in exfactory inspection of products.