The main differences between hot rolling and cold drawn steel pipes

We are often asked how hot rolling and cold drawn steel pipes differs.There are the main differences between hot rolling and cold drawn steel pipes as follow:

Cold-formed steels allow local buckling of the cross-section so that the post-buckling bearing capacity can be fully utilized;whereas hot-rolled steels do not allow local buckling of the cross-section.

The causes of residual stress in hot-rolled steel and cold-rolled steel are different,so the distribution in cross-section is also very different.The type of residual stress’s contribution is curved on the cold-rolled steel,while the type of residual stress’s contribution is membrane on the hot-rolled steel.

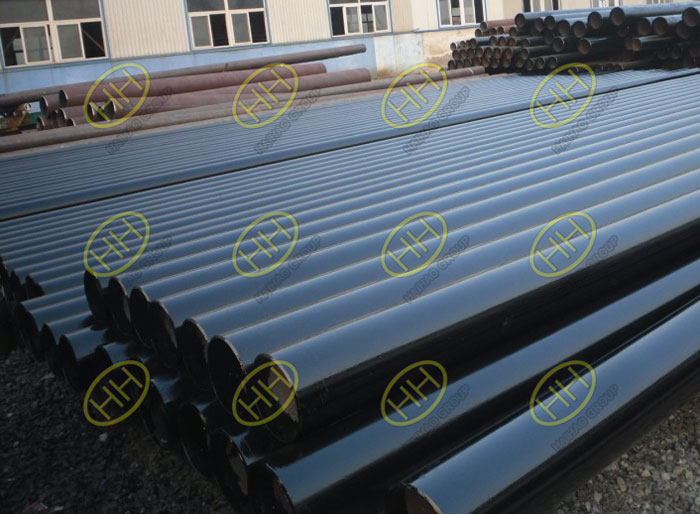

Carbon steel cold drawn steel pipes finished in Haihao Group

There is not much difference between the two kinds of steel pipes when finished the production.Generally,they are manufactured according to the standard.So there is no difference in the mechanical properties.Most of the differences exist in the processing technology,and the final accuracy.In general,the cold drawing pipe’s dimension is more accurate and the surface is smoother.

Hot rolling steel pipes process:

Tube blank—heating—perforation—rolling tube—sizing block—cold frame—straightening— cutting—testing—packing—delivering

Cold drawing steel pipes process:

Tube blank—heating—perforation—hot rolling—heading—pickling—phosphating—cold drawing—annealing—Straightening—Cutting— Inspection—Packaging—Delivery

Carbon steel hot rolled steel pipes finished in Haihao Group

Haihao Group supply hot rolling steel pipes and cold drawing steel pipes more than 30 years,we owns advanced production lines.Products are manufactured by forging,cold pressing,cold forming,hot extrusion,heat treatment,polishing,rubbing,machining and chrome finishing.There are many advanced machines,such as heat treatment furnaces,automatic welding machines,large lathe and inspection devices more than 100 sets.For more information,you can feel free to contact us email:sales@haihaogroup.com