Advantages and disadvantages of cold drawing and hot rolling

For the rolling mill,there are hot rolling mill and cold rolling mill.So for the rolling process,there are hot rolled and cold rolled.Regarding these two rolling methods,where are their advantages and disadvantages? In the following,we will make a specific analysis and elaboration between them,so that you can have a good knowledge about this.

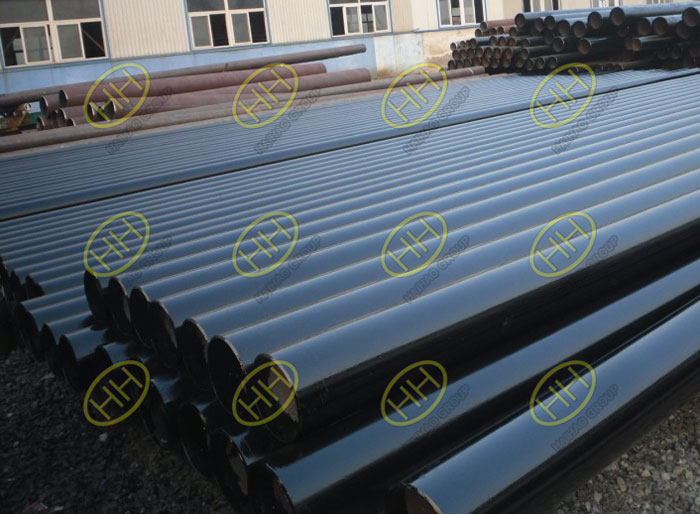

Carbon steel hot rolled steel pipes finished in Haihao Group

Advantages and disadvantages of hot rolling:

Advantage of hot rolling:

It can destroy the ingot casting structure,refine the grain of the steel, and eliminate the defects of the microstructure,so that the steel structure is dense and the mechanical properties are improved.This improvement is mainly reflected in the rolling direction,so that the steel is no longer isotropic;to a certain extent,the bubbles,cracks and looseness formed during casting can also be welded under high temperature and pressure.

Disadvantages of hot rolling:

After hot rolling,the non-metallic inclusions (mainly sulfides and oxides,and silicates) inside the steel are pressed into thin pieces and a delamination (sandwich) phenomenon occurs.

Residual stress caused by uneven cooling.The larger the size of the general steel section,the greater the residual stress.Residual stress can have adverse effects on deformation,stability,and fatigue resistance.

Hot-rolled steel products have poor control over thickness and side width.We are familiar with thermal expansion and contraction.When it is started,hot rolling produces even the length and thickness are acceptable.Finally,after cooling,there will be a certain negative difference.

Cold Rolled Seamless Steel Pipes Manufacturer

Advantages and disadvantages of cold rolling

Advantage of cold rolling:

Cold-rolling forming speed,high yield,and does not damage the coating,can be made into a variety of cross-section forms to meet the needs of the use conditions;cold-rolling can make the steel produce a large plastic deformation,thereby increasing the yield of the steel point.

Disadvantages of cold rolling:

Although there is no thermal plastic compression in the forming process,residual stresses still exist in the cross section,which will inevitably affect the overall and local buckling properties of the steel.

The cold-rolled section steel pattern is generally open section,so that the free torsional stiffness of the section is low.It is easy to twist when being bent,bending and torsion buckling tend to occur during compression,and the torsion resistance is poor;

The wall thickness of the cold-rolled formed steel is relatively small,and it is not thickened at the corner where the plate joins.The ability to withstand localized concentrated loads is weak.

Haihao Group supply hot rolling steel pipes and cold drawing steel pipes more than 30 years,we owns advanced production lines.If you want to know more about the difference between hot rolling and cold drawn steel pipes,please feel free to contact us email:sales@haihaogroup.com