How to distinguish hot rolled and cold rolled seamless steel pipe?

As an important part of steel products,steel pipes are divided into two categories,seamless steel pipes (round billets) and welded steel pipes (plate with blank) because of their different manufacturing processes and the shape of the pipe blanks used.Generally seamless steel pipes are made by hot rolling or cold rolling with 10,20,30,35,45 high quality carbon steel and 16Mn,5MnV low alloy structural steel or 30CrMnSi, 40Cr, 45Mn2,40MnB alloy steel.

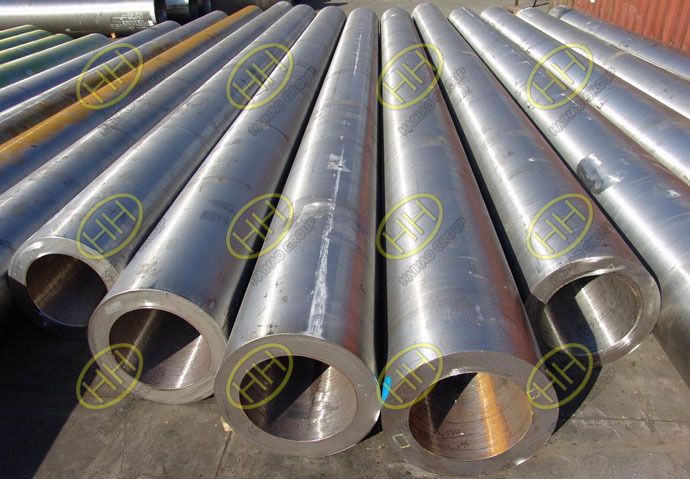

Hot rolled(extrusion) seamless steel pipe:

Hot rolling is relative to the cold rolling.Cold rolling carries on rolling below the temperature of recrystallization,and hot rolling is above the recrystallization temperature.Hot rolled seamless steel pipe is generally divided into low,medium,high pressure boiler steel pipe,alloy steel pipe, stainless steel pipe,oil cracking pipe,geological steel pipe and other steel pipe.The outside diameter of hot rolled seamless tube is generally greater than 32mm and the wall thickness of that is 2.5-75mm.

Hot Rolled Seamless Steel Pipes Manufacturer

Advantage of hot rolling seamless steel pipe:

Hot rollded seamless steel pipe can damage the cast microstructure of the steel ingot,refinement of the crystal grains of the steel,and eliminate the defects of the microstructure,so that the the steel organization compacting,improve the mechanical properties.This improvement is reflected in the rolling direction,so that the steel is no longer to a certain extent isotropic;pouring the formation of bubbles,cracks,and osteoporosis,under high temperature and pressure can also be welded together.

The technological process of hot-rolled(extrusion) seamless steel tubes:

Tube blanks→Heating→Punching→Three-roller oblique rolling,continuous rolling or extrusion→tube knockout→Sizing block(or reducing)→Cooling→Blow tube→Heat straightening→Hydraulic test (or flaw detection)→Marking→Warehouse.

Cold Rolled Seamless Steel Pipes Manufacturer

Cold rolled (drawn)seamless steel pipe:

Cold rolled seamless tube is a seamless steel tube for high dimensional accuracy and good surface finish.Cold rolled seamless pipe in addition to include the general steel,low and medium pressure boiler tube,high-pressure boiler tubes,alloy steel pipe,stainless steel pipe and oil cracking tube,also includes carbon thin wall steel pipe,alloy thin wall steel tube,thin-walled stainless steel pipe and special-shaped steel tube.The diameter of cold rolled seamless steel pipe is 6mm,wall thickness is 0.25mm,while the diameter of thin-walled tube can be 5mm,wall thickness can less than 0.25mm.The dimensional accuracy of cold rolling is higher than that of hot rolling.

Advantage of cold drawn seamless steel pipe:

Forming fast,high yield,and no damage to the coating,it can be made into a variety of cross sectional form to meet the needs of the use of conditions;Cold rolling can cause great plastic deformation,so as to improve the yield of the steel.

The technological process of cold-drawn(rolled) seamless steel tubes:

Tube blanks→Heating→Punching→Heading→Annealing→Pickling→Oil coating (copper plating)→Many times cold drawing (cold rolling)→ Blank tube→Heat treatment→Straightening→Hydrostatic test (flaw detection)→Marking→Warehouse.

Haihao Group can provide these two types seamless steel pipes in high quality,our products used well all over the world.For more information,please feel free to contact us email:sales@haihaogroup.com