Simple ways to detect the quality of stainless steel elbow

Stainless steel elbow is a common type of pipe used to change direction during pipe construction. And because of the particularity of stainless steel elbow, so this elbow wide application, excellent performance. Of course, even if the factory’s production rate is guaranteed, some stainless steel elbows will have certain defects. Let’s explore the welding quality inspection method of stainless steel elbows together:

Appearance inspection

Usually with the naked eye, sometimes with a magnifying glass of 5-20 times. Surface defects in welded elbows can be found by appearance inspection. Such as bottom cutting, welding processes, pores, flux, surface cracks, welding depth, etc. The shape and size of rounded corners can also be measured with a rounded detector or template.

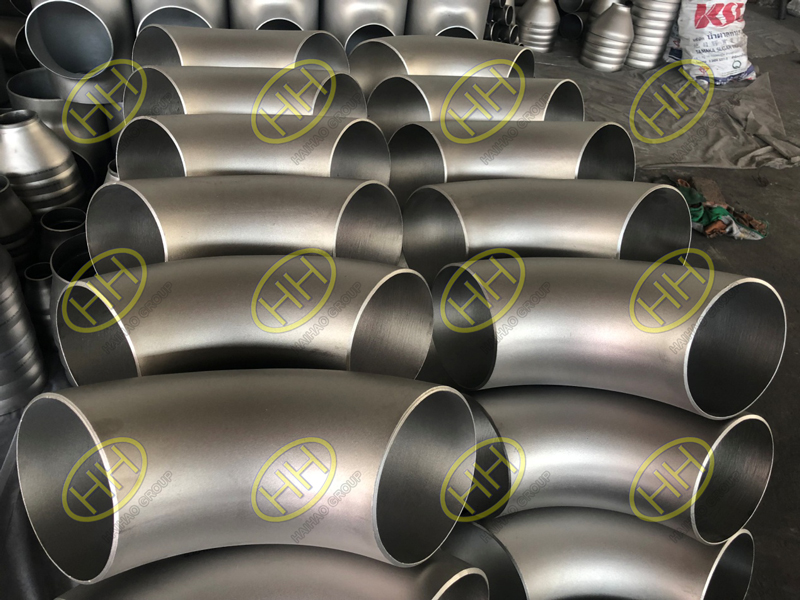

Stainless steel 90 degree elbows

Mechanical property test of elbow

Nondestructive testing may reveal defects in the weld and may require tensile, impact, and bending tests on the welded joints.

These tests are performed by the test team. It is best to weld the test plates to the longitudinal joints of the cylinders to ensure consistent construction conditions. In the actual production, the welding joint of New steel was only tested in this area.

Hydrostatic and barometric tests

For pressure vessels that need to be sealed, a hydrostatic or barometric test is required in order to check the tightness of the solder joints.

The method is to inject water or gas (mainly air) at 1.25 to 1.5 times the working pressure of the vessel. After holding for some time, observe the pressure drop inside the container. Observe the external leakage phenomenon and evaluate the welding quality.

Hope these simple methods of detecting the quality of stainless steel elbows will help you. Haihao group has many years of experience in producing and testing stainless steel elbow, hoping to provide better service for new and old customers.