An effective and convenient method to solve flange corrosion

The integrity of the flange connection is critical to the fluid pipeline system. Whether it is a pipeline system that transports chemical media (such as hydrocarbons) or a water supply pipeline, flange connection leakage can cause serious environmental and economic impacts, and may even bring huge safety risks. If the flange is not protected, the corrosion rate will be very fast if it is exposed to a corrosive environment or a polluted industrial atmosphere. In addition, due to the complicated geometry of the flange connection, the gap corrosion between the two flange surfaces and galvanic corrosion between different metals are very easy to cause, which will seriously damage the integrity of the pipeline system. Several practical methods of corrosion.

The ideal solution should take into account excellent corrosion protection performance and simple construction procedures, and should be suitable for flanges of various sizes and shapes, and can easily operate bolts during maintenance. Solutions commonly used in the market today include:

Flange coating with interthane-990-Polyurethane

1.Maintain paint solutions

Maintenance paint is a hard film that can be directly bonded to the substrate, generally epoxy or polyurethane-based coatings. The flange has many edges and edges. Due to the thinning effect of the edge, it is difficult for the conventional paint system to effectively cover the edge. Although the thick coating will solve the problem of edge protection, it will also seal the fastener and make it impossible to remove during subsequent repairs. In addition, the coating will be damaged when the bolt is operated, and it must be repainted after maintenance.

2.Mechanical solutions

The flange and the gap on the flange surface are mainly sealed by the protective cover and the clamp. Usually stainless steel or plastic materials are equipped with rubber sealing strips. This type of protection is less flexible and requires storage of housings or fixtures that are perfectly matched to flanges of various sizes.

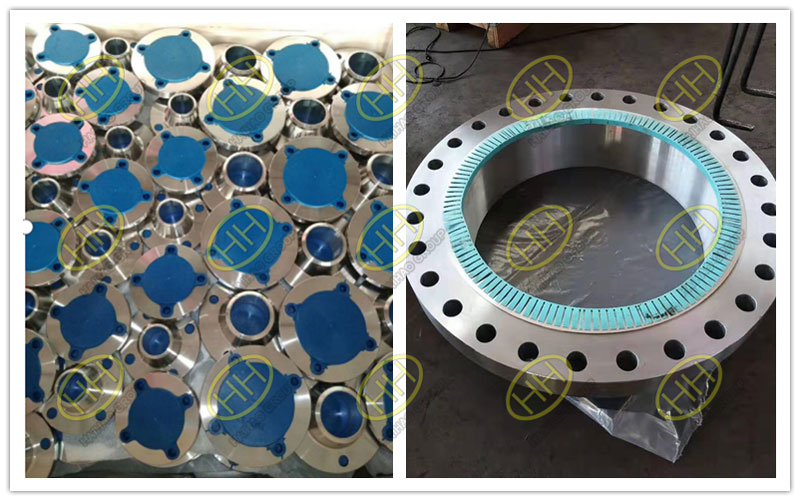

Flange sealing face protector

3.Tape or semi-solid anti-corrosion tape solution

Rolled packaging tapes (such as petrolatum tapes, waxy or elastic polymer bandaging tapes) are protected by wrapping on the surface of the substrate. Because semi-solid polymers have better water resistance, this protection method can provide reliable corrosion protection.

However, if the large flange has a complex shape, this material is not only time consuming but also difficult to construct. When bolts need to be disassembled, the material is relatively soft and easy to cut, but it is difficult to reseal and restore the original protection after disassembly, and generally requires re-construction.

Bubble wrap packing,anti-tarnish paper and bag for flanges

4.Hot-melt plastics solutions

Hot melt plastic is essentially a waxy fusible polymer heated at a high temperature, which is sprayed onto the surface of the substrate through professional hot melt equipment. The advantage of this protection method is that it can be remelted and reused, which saves costs. However, this method also requires hot work, professional equipment and construction services. Although it can be reused, it is not easy to open and seal during maintenance.

These are the 4 mainstream practical methods for solving flange corrosion adopted in the industry at present. Our company has many years of experience in solving flange corrosion problems for customers. We have made many customized solutions according to the actual situation of customers. You want to know more engineering cases and learn more comprehensive methods.