Advantages of ASTM A105N Forged Socket Weld Fittings in High-Pressure Piping Systems

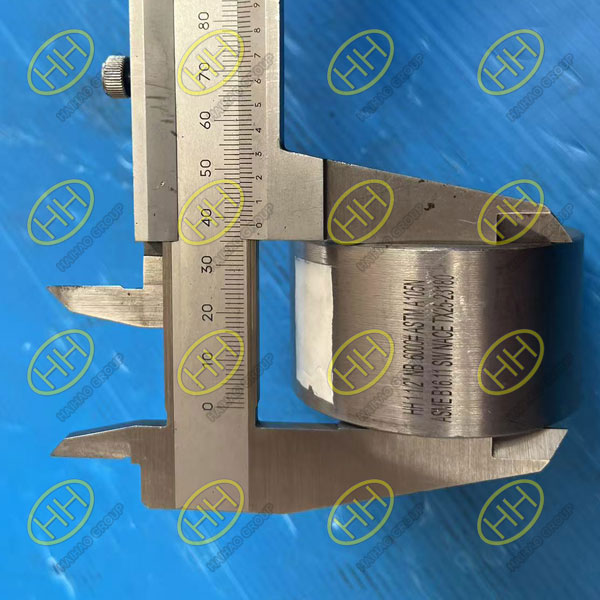

For high-pressure piping systems in the oil, gas, petrochemical and power generation industries, choosing the right materials and connection methods is critical to long-term reliability and safety. ASTM A105N socket welding pipe fittings are one of the most trusted solutions. Recently, Haihao Group has produced a variety of forged socket fittings for Singapore customers, including elbows, tees, sockelets, etc. These forged parts are usually produced in accordance with ASME B16.11 standards, with pressure ratings up to 6000#, ensuring excellent mechanical strength and sealing performance.

ASME B16.11 ASTM A105N Forged Socket Weld Fittings

What Is ASTM A105N?

ASTM A105N is a standard specification for forged carbon steel piping components suitable for ambient- and high-temperature service. The “N” in A105N indicates that the material has been normalized, a heat treatment process that improves its grain structure and toughness.

Key chemical requirements for these A105N Forged Socket Weld Fittings include:

- Carbon (C) ≤ 0.23%

- Sulfur (S) ≤ 0.020%

- Phosphorus (P) ≤ 0.025%

- Carbon Equivalent (CE) ≤ 0.43%

Additional mechanical requirements:

- Hardness ≤ 187 HBW

- Normalizing or normalizing + tempering heat treatment

- If tempered, tempering temperature ≥ 620°C

- Supplied with EN 10204 3.1 certificate upon request

These characteristics enable the batch of ASTM A105N socket fittings produced by Haihao Group for Singapore customers to exhibit stable performance under high temperature and high pressure environments.

ASME B16.11 ASTM A105N Sockolet

Advantages of Socket Weld Connections

Socket weld fittings offer several engineering and operational advantages over other connection methods, particularly in high-pressure systems:

1.High structural integrity: The socket weld design provides a strong mechanical joint, capable of handling sudden pressure surges.

2.Leak-proof connection: Welded joints offer superior sealing compared to threaded joints, reducing the risk of leakage.

3.Compact installation: The fittings are compact and easy to install in tight or restricted spaces.

4.Ideal for small bore piping: Typically used for pipe sizes up to 2 inches, socket weld fittings are especially suitable for high-pressure instrumentation lines and utility piping.

ASME B16.11 Industry Standard for Forged Fittings

ASME B16.11 defines the dimensions, tolerances, material grades, and pressure ratings for forged fittings including elbows, tees, caps, couplings, and outlets. It ensures consistency across manufacturers and compatibility with standard pipe sizes.

Haihao Group manufactures ASTM A105N socket weld fittings strictly in accordance with ASME B16.11, ensuring:

1.Accurate dimensions and tolerance control

2.Pressure classes up to 6000#

3.Full traceability and material test reports (MTRs)

4.Certification to EN 10204 3.1

ASME B16.11 ASTM A105N Forged Socket Weld Coupling

Applications in High-Pressure Piping Systems

Forged ASTM A105N socket weld fittings are widely used in critical applications such as:

1.Oil and gas production – Wellheads, manifolds, and flowlines require high-pressure, corrosion-resistant fittings.

2.Refineries and chemical plants – Process systems demand fittings that can handle thermal cycling and aggressive chemicals.

3.Power generation – High-temperature steam and water systems benefit from A105N’s mechanical strength and thermal stability.

4.Offshore platforms – Space constraints and high-pressure environments make socket welds the preferred choice for small bore piping.

In demanding industrial settings, selecting the right fitting can make the difference between safe operation and costly failure. ASTM A105N forged socket weld fittings manufactured according to ASME B16.11 offer unmatched reliability, strength, and compatibility for high-pressure systems. Whether you’re operating in upstream oil and gas or heavy industrial plants, these fittings ensure optimal performance, safety, and compliance with global standards.

Haihao Group is a trusted supplier of forged pipe fittings with decades of manufacturing experience. We offer a complete range of socket weld elbows, tees, couplings, caps, and sockolets in A105N material, with full quality documentation and global shipping support.

Contact us today to get a quote or learn more about our high-performance forged fitting solutions. Email:sales@haihaogroup.com