How to do reinforcement welded tee?

Tee branch connection is weakened because of its complicated stress distribution,so it is necessary to provide added reinforcement when the tee is under much pressure .Generally there are three kinds of reinforcement methods,they are reinforcing pad,single-reinforcement and reinforcing saddle.

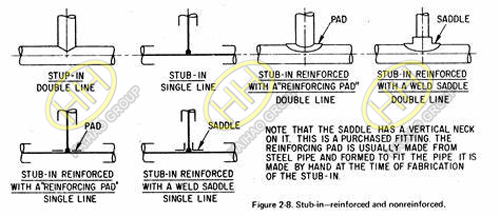

With large pipe dimensions,it is customary, to form a tee intersection by cutting a hole in the straight run (the header) and welding in the branch, this is called a STUB-IN, as shown below.

Stub In

A Repad, also known as a Reinforcing Pad, is a donut shaped pad that goes around the branch of a branch joint to add strength to the joint. There are several optional shapes for the outside edge of the pad. Also, the template generated will be different depending on the shape of the raw material used.

Reinforcing pad

Among the various reinforcement welded tees, the use of a single reinforcement method can effectively improve the strength performance of the mother pipe, and it is simple and easy to manufacture. The single-reinforcement welding is carried out after the main weld has passed the radiographic inspection and has high technical requirements for the welder.

Single-reinforcement reinforcement welded tee

Single-reinforcement reinforcement welded tee

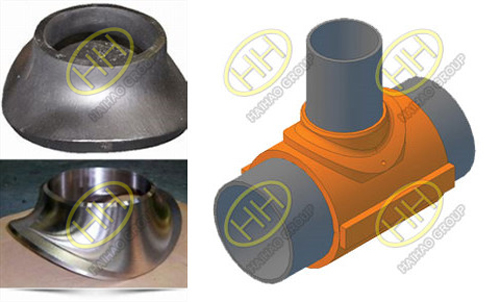

Reinforcing saddles provide reinforcement for tee branch and header connections in accordance with ASME B31.3, B31.4, B31.8. Reinforcing saddles do not wrap around the header pipe like full encirclement saddles. Reinforcing Saddle are used to provide reinforcement for branch outlets. Saddles include a vent hole to prevent entrapment of gasses during welding. (What is full-encirclement reinforcing saddle?)

Reinforcing saddle

Haihao Group can supply all kinds of these reinforcement welded tees. If you have any questions, please feel free to email us: sales@haihaogroup.com