Stub Ends for Flanged Joints

What is a stub end and why should it be used?

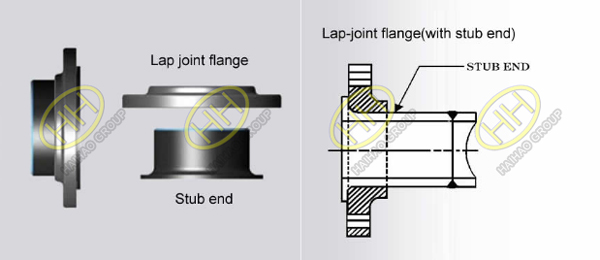

Stub ends are butt weld fittings that can be used (in combination with a lap joint flange) alternatively to welding neck flanges to make flanged connections. The use of stub ends has two advantages: it can reduce the total cost of flanged joints for piping systems in high material grades (as the lap joint flange does not need to be of the same material of the pipe and the stub end but can be a lower grade); it speeds up the installation process, as the lap joint flange can be rotated to facilitate the alignment of the bolt holes. Stub ends are available in short and long pattern (ASA and MSS stub ends), in sizes up to 80 inches.

ASTM A403 Grade 316 MSS SP-43 lap joint stub end Type B finished in Haihao Group

A stud end and a lap joint flange can be used together as an alternative way to make a flanged connection than welding neck flanges.

The stub end, which is essentially a piece of pipe, with one end flared outwards and the other prepared to be welded to a pipe of the same bore size (NPS = nominal pipe size), material and wall thickness. The most widely used fabrication tool for stub ends is the flaring machine, which is able to flare the end of the pipe and then cuts it to length.

Lap Joint Flange

A lap joint flange, which is used to actually bolt the two lengths of pipe together.

HEBEI HAOHAO GROUP supply all types of stub end such as TYPE A , TYPE B and TYPE C.If you want to know more about our products,please feel free to contact us.Email:sales@haihaogroup.com