Steel pipe elbows’ main production technology

The butt welding steel elbows manufacturing technology has no a definite standard,but there are a lot of practice in the pipe elbow industry. It is very terrible that the development of an industry does not has its own industry standard.We should pay attention to summarizing the regularity,and promote the friendly development of the pipe industry.(Fittings Production Video)

The elbow production way are mainly as follows:

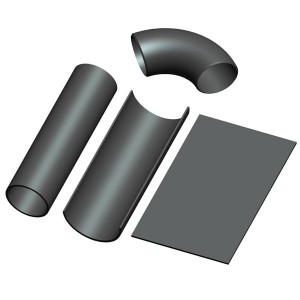

seamless-steel-elbows-production-process

1. Seamless butt welding elbows: they are made from the seamless pipes.Heating a seamless steel pipes and bending the pipe to the specifica angle needed,then it is a seamless steel elbow.This is the most widely used methods for elbows production in Hebei Haihao Group now.

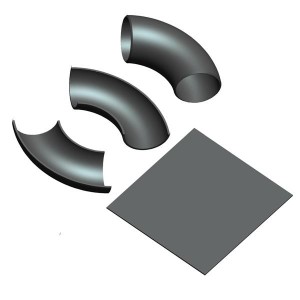

erw-steel-elbows-production-process

2. ERW steel elbows: they are welded elbow,not seamless,made from the ERW pipes.For the ERW elbows,the first production step is made a ERW steel pipe from a steel plate or steel coil,after that bending the ERW pipes to a elbow,this is the same process with the seamless elbows.Haihao Group now supply this to some clients who request this type elbows for low pressure application.

plate-welded-steel-elbows-production-process

3. Plate welded elbows: this kind of elbows are made from the steel plate directly, commonly it is big diameter elbow.People cut the steel plates and press the plate to the shape of half elbow,then weld the halves together to a elbow.This is the oldest production way we used in the first pipe fitting factory of Haihao Group in last century.

Hebei Haihao pipe fittings plants can produce all the three types of elbows,for the seamless steel elbows,the pre-inspection for the raw material is very important.For the ERW elbows and the plate welded elbows,the X-RAY test (RT) is necessary,the quality test for the welded joint (welded seam) is the most important thing for such kinds of elbows.