Operation process of bend processing and cleaning

In the process of bend,the service life of the anti-corrosion coating mainly depends on the type of coating, the coating quality of the product surface bend and the construction conditions and other factors. The impact of the surface treatment of bend processing on the service life of the product anti-corrosion coating accounts for about 50%, so it is necessary to treat the surface of the bend strictly according to the anti-corrosion coating standard of the bend.

Operation process of bend processing and cleaning:

In the process of cleaning the bend, the emulsion and solvent should be used to clean the steel surface effectively, which can effectively remove the organic matters of grease, oil and smooth agent, but this method can not remove the rust, oxide skin and flux on the steel surface.

In the process of operation, the surface of the bend needs to be effectively polished with steel wire brush and other things, which can remove the raised oxide skin, rust, welding slag, etc. The derusting of hand tools can reach level SA2.

Operation process of bend processing and cleaning

If the chemical and electrolytic methods are effectively used for the pickling treatment of bend, the chemical pickling will only be used for the corrosion protection of bend, so that the oxide scale, rust and old coating can be effectively removed to a certain extent.

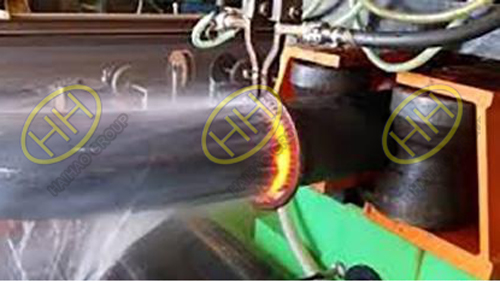

The effective use of the chemical cleaning of the bend can make the appearance reach the necessary degree of cleanliness and coarseness to a certain extent, but its shallow anchor pattern will effectively form its pollution to the situation. The spray rust removal of the product is driven by the high-power motor to rotate the spray blade at a high speed.

The bend will effectively use its wire section, steel shot, steel sand and other abrasives, and effectively spray the surface of the bend under the effect of centrifugal force, which can not only completely eliminate rust, oxide and dirt in the process of processing.

As a professional supplier of pipe fitting,we have more than 30 years of experience in this industry.If you have any problem,please contact us.Email:sales@haihaogroup.com