Nickel Alloy Weldolet for Offshore Client in Singapore

Earlier this month, we completed the production and dispatch of a custom nickel alloy weldolet order for a long-standing client in Singapore. The parts are destined for use in a subsea piping system, where corrosion resistance and mechanical reliability are critical due to high salinity and fluctuating pressure conditions.

This was not a high-volume job—but it required precision, proper documentation, and full compliance with international materials and welding standards.

WELDOLETS NICKEL ALLOY ASTM B366 UNS N06625 ASME B16.9 MSS SP-97

Product Summary

Type: Weldolet (Branch Fitting)

Run Pipe Size: 6”

Branch Size: 2”

Wall Thickness (Run x Branch): 21.95 mm x 8.74 mm

Material: Nickel Alloy – ASTM B366 UNS N06625

Standard: ASME B16.9 / MSS-SP-97

Compliance: NACE MR0175 (for sour service environments)

Project Requirements

The client’s main concern was material integrity under aggressive conditions. UNS N06625 (Alloy 625) was specified due to its excellent resistance to seawater corrosion, pitting, and chloride-induced stress corrosion cracking. The fittings needed to be fully compliant with both ASME B16.9 for dimensions and MSS-SP-97 for branch connections.

We also had to certify compliance with NACE MR0175, ensuring the fittings were suitable for sour service and H₂S exposure.

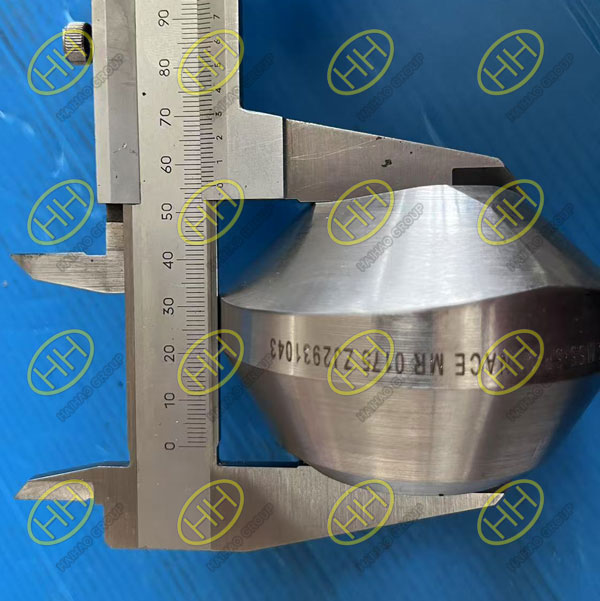

QUALITY INSPECTION FOR WELDOLET NICKEL ALLOY ASTM B366 UNS N06625 ASME B16.9 MSS SP-97

Manufacturing Notes

The weldolets were machined from forged nickel alloy billets sourced from a NORSOK-approved supplier. Special care was taken during:

CNC profiling of the saddle radius to match the 6″ header pipe curvature

Precise bevel machining on the 2″ branch end for welding compatibility

Wall thickness control, with ultrasonic testing performed on critical dimensions

Each fitting was solution-annealed and pickled to remove surface oxidation and ensure weld cleanliness.

Testing & Certification

Visual and dimensional inspection per MSS-SP-97

PMI (Positive Material Identification) using XRF gun for UNS N06625 confirmation

Ultrasonic wall thickness verification

NACE MR0175 statement of compliance provided in documentation

Heat numbers, batch numbers, and melt origin were laser-etched on each part for traceability.

Export & Delivery

Given the relatively small volume, we packed the fittings in a compact but reinforced plywood crate. Each piece was sealed in VCI (vapor corrosion inhibitor) bags and separated with foam blocks to avoid contact damage. Crate labels included full material spec and PO number, ensuring a smooth customs clearance on the Singapore end.

The shipment was released ahead of schedule and left our facility via air freight for fast delivery, per the client’s request.

Projects like this remind us that even small orders carry big technical responsibility—especially when they’re headed offshore. There’s no room for shortcuts when a fitting is going onto subsea pipework where corrosion and fatigue failures aren’t just costly—they’re dangerous.

If you’re sourcing nickel alloy weldolets, UNS N06625 branch fittings, or need custom-machined parts that meet MSS SP-97 and NACE MR0175, we’re equipped to support it with full material traceability and short lead times.