Introduction to boilers and pressure vessels

What are Boilers and Pressure Vessels?

Boilers are closed vessels designed to heat water or produce steam under pressure for industrial applications such as power generation, chemical production, and ship propulsion.

Pressure Vessels are containers designed to hold gases or liquids at a pressure substantially different from ambient pressure. These are widely used in industries such as oil & gas, petrochemical, and food processing.

Boilers and Pressure Vessel

Key Differences Between Boilers and Pressure Vessels:

| Aspect | Boiler | Pressure Vessel |

|---|---|---|

| Function | Generates steam or hot water | Stores fluids/gases under pressure |

| Design Code | ASME Section I | ASME Section VIII Division 1/2/3 |

| Working Medium | Water, Steam | Gases, Liquids |

| Typical Pressure | 15-3000 psi | 15-10000 psi |

| Testing | Hydrostatic + Steam Test | Hydrostatic or Pneumatic |

Applicable International Standards

ASME Boiler and Pressure Vessel Code (BPVC):

Section I: Power Boilers

Section IV: Heating Boilers

Section VIII: Pressure Vessels

PED 2014/68/EU: European Pressure Equipment Directive

EN 13445: European standard for unfired pressure vessels

API 510 / API 570: Maintenance & inspection guidelines

Basic Design & Calculation Principles

Thin-Walled Cylinder Stress Formula (When D/t > 20):

- Hoop Stress (σθ): σθ = (P * r) / t

- Longitudinal Stress (σL): σL = (P * r) / (2t)

Where:

- P = Internal pressure

- r = Internal radius

- t = Wall thickness

Thick-Walled Cylinder (When D/t ≤ 20):

Apply Lamé equations considering radial stress gradients.

pressure vessels for Singapore

Material Selection

| Material Type | Example Grades | Applications |

| Carbon Steel | SA-516 Gr.70, SA-285 | Low/medium pressure vessels |

| Stainless Steel | 304/316/321/347 | Corrosive fluids, food-grade vessels |

| Duplex Steel | S31803, S32750 | Offshore, sour gas environments |

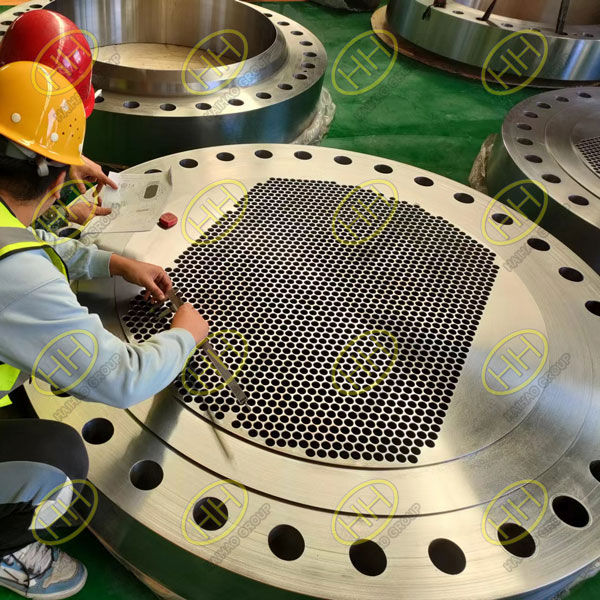

Manufacturing Processes

- Plate Rolling & Welding (SAW, TIG)

- Forging (Heads, Flanges)

- Heat Treatment (PWHT)

- Non-Destructive Testing (RT, UT, MT, PT)

- Pressure Testing (Hydrostatic, Pneumatic)

Inspection & Certification

ASME “U”, “U2” Stamp for Pressure Vessels

ASME “S” Stamp for Boilers

Hydrostatic testing at 1.3 times design pressure

Third-party inspection: SGS, BV, Lloyd’s

FAQs

Q1: What’s the difference between ASME Section I and Section VIII?

A1: Section I covers boilers generating steam for power; Section VIII covers vessels for storing gas/liquid under pressure.

Q2: When is thick-wall design needed?

A2: When the internal diameter to wall thickness ratio (D/t) is less than 20.

Q3: Can pressure vessels also act as boilers?

A3: Generally no, but heat exchangers sometimes integrate both functions

Petrochemical Refinery in Singapore: Designed and fabricated 50 pressure vessels (SA-516 Gr.70) for ammonia storage, ASME VIII Div.1 certified, PWHT, RT 100%, hydrotested to 1.5 MPa.

Contact Us for Boiler & Pressure Vessel Solutions, Email: sales@haihaogroup.com