Integrally formed tee,how much do you know?

In the previous article,(Not choosing such a tee will cost you a lot of money) we learned that prone problems can occur at the tee branch,so do you know how this problem happen?

Do you know what the production process of integrally formed tee is?

Here’s the answer for you.

There are two manufacturing process for integrally formed tee, one is Hydraulic Bulging Forming,the other is Hot Pressing Forming.

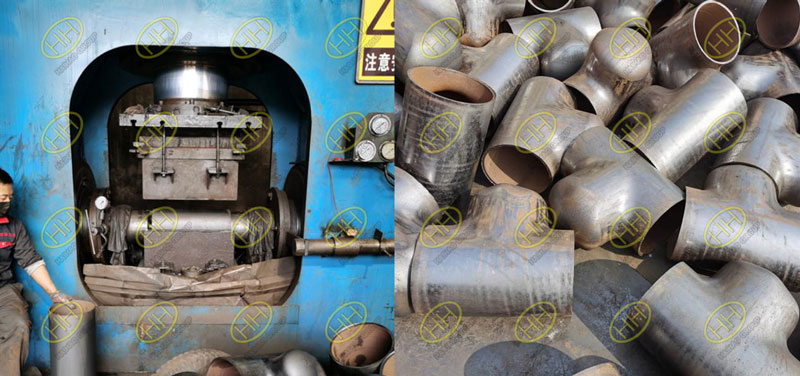

Hydraulic bulging forming process for integrally formed tee

Hydraulic bulging is a forming process that bulges the branch pipe through the axial compensation of the metal material. The tee hydraulic bulging process can be formed one time, and the production efficiency is high. Due to the large tonnage of equipment required for the hydraulic bulging process of the seamless tee, it is mainly used in the manufacture of standard wall thickness of tees with size below DN400 in China.

Hot pressing forming process for integrally formed tee

The entire process of hot press forming is formed by the radial compression of the tube blank and the drawing process of the branch pipe. The metal of the hot-pressed tee branch pipe is compensated by the radial motion of the tube blank, so it is also called the radial compensation process. The hot pressing tee has a wide adaptability to materials, and is suitable for low carbon steel, alloy steel, and stainless steel; especially the tees with large diameters and thick tube walls.

Whichever the manufacturing process is, the wall thickness of tee branch will become thin. So it requires relevant test to measure the quality.

For other type of tee,how much do you know?