How to detect the internal corrosion of elbow?

Elbow is a metal pipe fitting that changes the direction of the pipe on the pipe. The connection methods are screw thread and welding. According to the angle, there are 45 ° and 90 ° 180 ° three most commonly used, in addition, according to the needs of the project, there are also 60 ° and other abnormal angle elbows.

In the actual use process of elbow, whether it is stamping elbow or pushing elbow, because of the transportation of corrosive media, with the increase of service time, the inner membrane of elbow will slowly appear corrosion. And because we can’t visually observe the corrosion inside the elbow, we can’t get the correct data and corrosion parts of the elbow, which makes us very anxious.

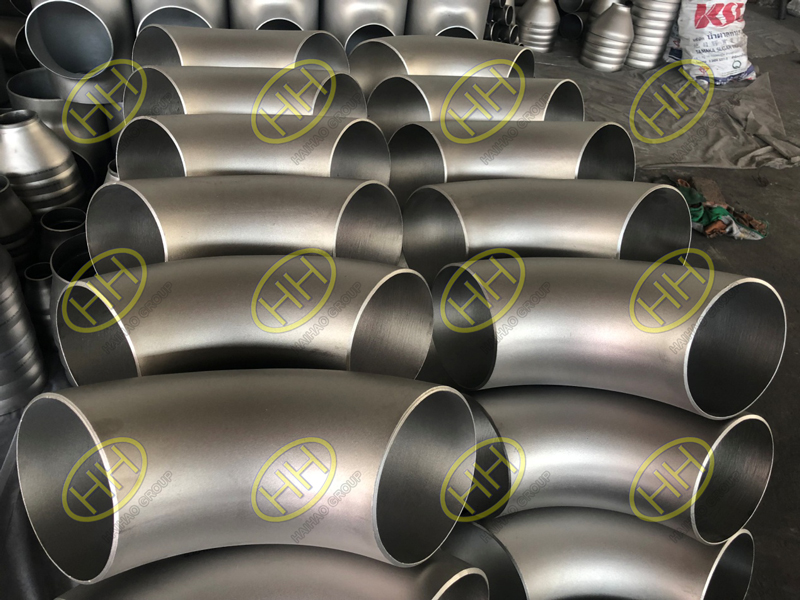

Stainless steel 90 degree elbows

At present, there are two widely used methods to detect the internal corrosion of elbow in China: ultrasonic detection method and flux leakage method. Different detection methods have different detection principles and processes:

(1) Ultrasonic detection of elbow internal corrosion

The detection principle of ultrasonic detection method is the principle of ultrasonic pulse reflection. When testing, the probe will send ultrasonic pulse vertically to the inner wall of the pipe. The probe first receives the reflected pulse from the inner surface of the pipe wall, and then the ultrasonic probe will receive the reflected pulse from the outer surface of the pipe wall. The distance between the pulse and the reflected pulse on the inner surface reflects the thickness of the pipe wall.

ASME B16.9 A234 WPB 45 degree short radius elbows

(2) Detection of internal corrosion of elbow by magnetic flux leakage method

The basic principle of flux leakage testing is based on the high permeability of ferromagnetic materials. The permeability of steel pipe corrosion defects is far less than that of steel pipe, and the steel pipe is magnetized under the action of external magnetic field. When there are no defects in the steel pipe, most of the magnetic lines pass through the steel pipe, and the magnetic lines are evenly distributed; when there are defects in the steel pipe, the magnetic lines bend, and a part of the magnetic lines leak out of the steel pipe surface. The existence of defects can be judged by detecting the leakage flux on the surface of magnetized steel pipe.

Haihao Group manufacture elbow products more than 30 years,the products sells well all over the world for the high quality.If you have any question,please contact us! Email:sales@haihaogroup.com