How many pieces of bar should be welded to barred tee?

Barred tees are manufactured to specific customer project specifications in a full range of sizes same as butt weld tee.Custom fitted bar sections are welded to the branch of the butt weld tee.The bars are added to ensure the pig passes by the branch opening.Bar spacing is designed to prevent damage to the functional elements of the pig.However,how many pieces of the bar should be welded to the branch of the tee ?

If the bar welded are too many,maybe reduce the medium flow. If too small,maybe don’t have function when the pig pass. There is no international standard dimension for the barred tee. It is custom made using the ASME B16.9/ MSS-SP 75 tee as a base. However, many develop their barred tee based on Shell DEP 31.40.10.13-Gen or ISO 15590-2 standard.

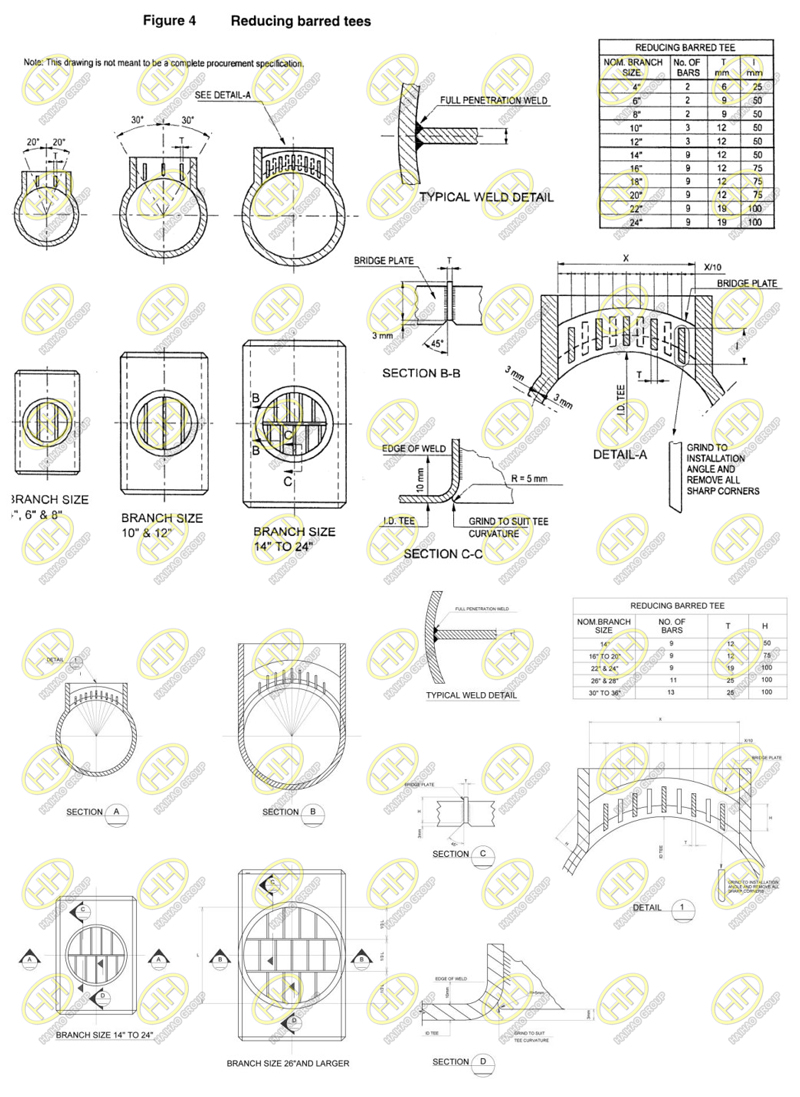

Reduced Barred Tee (Reference: Shell DEP 31.40.10.13-Gen Figure 4)

If there are no request in the PO specification,usually, the bars quantity according to the manufacturer’s standard.

Reducing barred tee drawing

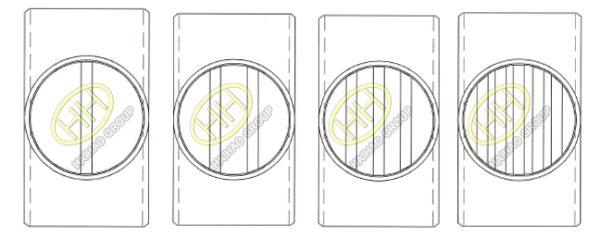

Equally spaced bars for size 4″ to 6″ is 1 bar, 8″ to 10″ is 2 bars,12″ to 20″ is 3pcs and 24″ to 48″ is 5 bars. And the thickness for 4″ to 18″ bars is 1/2″(12.7mm),and 20″ to 48″ is 7/8″(22.23mm).

The design of the bar plates must be in sufficient quantity, thickness and adequately spaced to ensure the smoothness for the pig to run through the main pipe, and at the same time not affecting the flow that was meant to flow through the branch. Normal practice is to ensure that the opening in the branch pipeline after guided bars is not more than 40% of the main pipeline area. Hebei Hiaho Group,as professional manufacturer of pipe fittings and flanges. Welcome your inquiry all the time.Email:sales@haihaogroup.com