How insulated joints protect underground pipeline from damage?

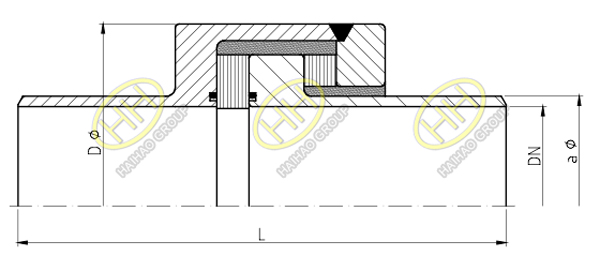

During the long underground pipeline installation,in order to protect pipeline from corrosion,need cathodic protection to be sued to the pipeline.Cathodic protection is usually applied by applying a forced current.If this current flow continues to the above-ground pipeline,it will damage the above-ground pipeline paint.Aim to cut the current flow from underground pipeline to above-ground pipeline.An insulated joints needed to be used.It’s designed in such a way that it will break the flow of current.Here in the image,you can see the configuration of insulation joint.

Configuration of insulation joint

The integral insulating joint is composed of upper and lower pipes,sleeves,insulating parts,seals and insulating coating.Insulation parts and seals are sandwiched between the butt ends of the upper and lower pipes of the insulation joint to form a double sealing structure with insulation performance.The sleeve adopts two forms of groove welding or direct welding with the upper conduit to seal the insulating parts and the upper and lower pipes firmly inside, forming a “sealed container”,which not only ensures good insulation effect,but also greatly improves the pressure bearing capacity of the insulating structure.

Insulation Joint

When the current flow meets the insulation joint,the insulating parts in the insulating joint play a role,it will it will break the flow of current.

Insulation joint is an essential and important pressure element in the cathodic protection system of steel pipeline,which is widely used in the cathodic protection system of steel pipeline.As a professional supplier,Hebei Haihao Group.Welcome to inquire and negotiate.Email:sales@haihaogroup.com