Haihao Group Supplies High-Strength Forged Pipes and Plates to Indonesia Project

Haihao Group has successfully completed the production and shipment of a batch of forged steel pipes and plates for an Indonesian client. The order includes a wide range of forged components manufactured from ASTM A694 F65, ASTM A350 LF2, UNS N06625, and UNS S31803/S32205 duplex stainless steel, all coated with protective oil to prevent corrosion during transportation and storage.

This delivery marks another milestone in Haihao Group’s ongoing commitment to providing high-strength forged piping products for global energy and industrial projects.

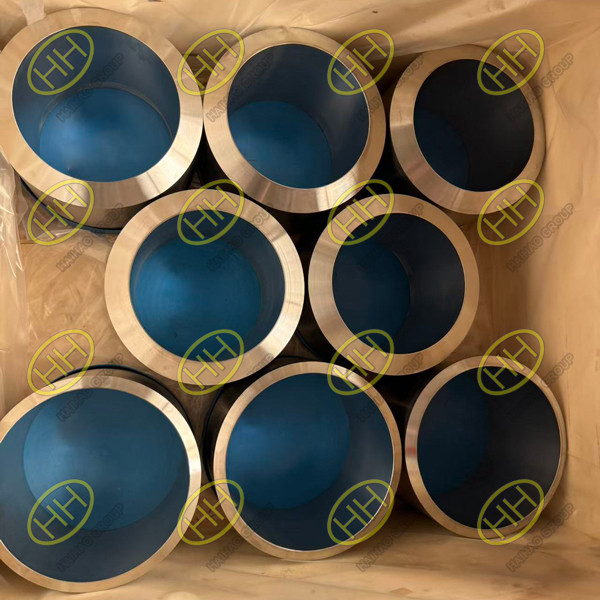

Duplex stainless steel forged pipes (UNS S31803S32205) with beveled ends

Product Overview

The shipment includes both forged seamless pipes and forged plates, precisely machined according to customer specifications. Each component was subjected to strict dimensional, metallurgical, and surface inspections before delivery.

Forged Seamless Pipes – ASTM A694 F65 & A350 LF2

- Outer Diameter: 323.9 mm to 355.6 mm

- Wall Thickness: 8 mm to 40 mm

- Length: 250 mm to 400 mm

- Ends: Beveled (25°) and plain ends

- Finish: Anti-rust oil coating

- Standards: ASTM A694 F65, ASTM A350 LF2 CL1

These carbon steel forged pipes are designed for high-pressure service in oil, gas, and petrochemical industries, offering excellent impact toughness and weldability.

Forged Seamless Pipes – Alloy and Duplex Stainless Steel

- Materials: UNS N06625 (Inconel 625), UNS S31803/S32205 (Duplex Stainless Steel)

- Outer Diameter: 323.9 mm to 355.6 mm

- Wall Thickness: 20 mm to 41.2 mm

- Length: 250 mm

- Ends: 25° beveled

- Finish: Protective oil coating

These pipes are used in corrosive and high-temperature applications, where resistance to chloride stress cracking and oxidation is critical. The Inconel 625 forged pipes are ideal for offshore platforms, while Duplex 2205 forged pipes ensure superior mechanical strength in harsh environments.

Forged Plate – ASTM A694 F65

- Dimensions: 400 mm (L) × 150 mm (W) × 38 mm (T)

- Material: ASTM A694 F65

- Surface Finish: Oil coating

The forged carbon steel plate offers high yield strength and excellent structural integrity, suitable for flanges, fittings, and pressure vessel applications.

Manufacturing Excellence

All forging processes at Haihao Group follow strict metallurgical controls, including:

- Precision forging and heat treatment to ensure homogeneous grain structure

- Ultrasonic and magnetic particle testing for defect detection

- Dimensional verification and surface inspection

- Oil coating application to prevent rust before shipment

Haihao’s in-house forging and machining facilities allow full control from billet selection to final inspection, guaranteeing that each product meets international standards and client requirements.

Application and Performance

The supplied forged components will be used in oil and gas pipeline systems, pressure vessels, and offshore installations in Indonesia. Thanks to their robust performance and corrosion resistance, these forged pipes and plates provide:

- High strength under elevated pressure and temperature

- Excellent weldability and toughness at low temperatures

- Extended service life under corrosive or marine exposure

- Dimensional accuracy for seamless system integration

This shipment reflects Haihao Group’s strong reputation as a trusted supplier of forged steel products for energy, petrochemical, and marine industries worldwide.

About Haihao Group

Haihao Group is a leading manufacturer and exporter of forged fittings, flanges, pipes, plates, and custom components for global pipeline systems. With advanced forging, heat treatment, and machining capabilities, the company provides complete pipeline connection solutions that meet ASME, ASTM, EN, and ISO standards.

From carbon steel and alloy steel to duplex stainless and nickel alloys, Haihao’s products are trusted by clients in Asia, Africa, Europe, and the Middle East for their precision, performance, and reliability.