What are the forming methods of elbow?

Elbow is one of the most commonly used piping products,it connects two pipes of the same or different nominal diameters so that the pipes rotate at an angle.According to the Angle,the most commonly used elbow is 45° and 90°180°. According to the engineering needs, other abnormal angle elbows such as 60° are also included.There are three forming methods of elbow:

The pushing process of pipe elbow

Hot push forming

The hot push elbow forming process is a process in which a special elbow pushing machine, a core die and a heating device are used to make the blank sheathed on the die move forward under the push of the pushing machine and be heated, enlarged and bent during the movement. The deformation characteristic of the hot push elbow is to determine the diameter of the tube blank according to the law that the volume before and after the plastic deformation of the metal material is constant. The diameter of the tube blank used is smaller than the diameter of the elbow. The deformation process of the blank is controlled by the core die, so that the metal compressed at the inner arc flows and compensates to other parts thinned due to the expansion, so as to obtain the elbow with uniform wall thickness.

Hot push elbow forming process has the characteristics of beautiful appearance, uniform wall thickness and continuous operation, which is suitable for mass production, so it has become the main forming method of carbon steel and alloy steel elbow, and also applied in the forming of some specifications of stainless steel elbow.

The heating mode of forming process includes medium frequency or high frequency induction heating (heating ring can be multi or single circle), flame heating and reflection furnace heating. The heating mode depends on the requirements of forming products and energy conditions.

Stainless steel forged threaded elbow A182 F316 90 degree

Stamping forming

Stamping elbow is the first forming process used in the mass production of seamless elbow. At present, it has been replaced by hot pushing or other forming processes in the production of elbow of common specifications. However, in some specifications of elbow, due to the small number of production, too thick or too thin wall thickness. The product is still in use when it has special requirements. The tube blank equal to the outer diameter of the elbow is used for the stamping of the elbow, and the press is used to directly press the elbow in the die. Before stamping, the tube blank is placed on the lower die, the inner core and the end die are loaded into the tube blank, the upper die starts to press downward, and the elbow is formed by the constraint of the outer die and the support of the inner die. Compared with the hot push process, the appearance quality of the stamping process is not as good as the former; the outer arc of the stamping elbow is in the drawing state during the forming, and there is no extra metal in other parts to compensate, so the wall thickness at the outer arc is about 10% thinner. However, due to the characteristics of single piece production and low cost, stamping elbow technology is mostly used in the manufacture of small batch and thick wall elbow.

Stamping elbow is divided into cold stamping and hot stamping. Usually, cold stamping or hot stamping is selected according to material properties and equipment capacity. The forming process of cold extrusion elbow is to use a special elbow forming machine to put the tube blank into the outer die. After the upper and lower dies are closed, the tube blank moves along the gap between the inner die and the outer die under the push of the push rod to complete the forming process. The elbow made by cold extrusion of internal and external die is beautiful in appearance, uniform in wall thickness and small in size deviation, so this process is mostly used for the forming of stainless steel elbow, especially for thin-walled stainless steel elbow. The internal and external die used in this process requires high precision, and the deviation of the wall thickness of the tube blank is also relatively strict.

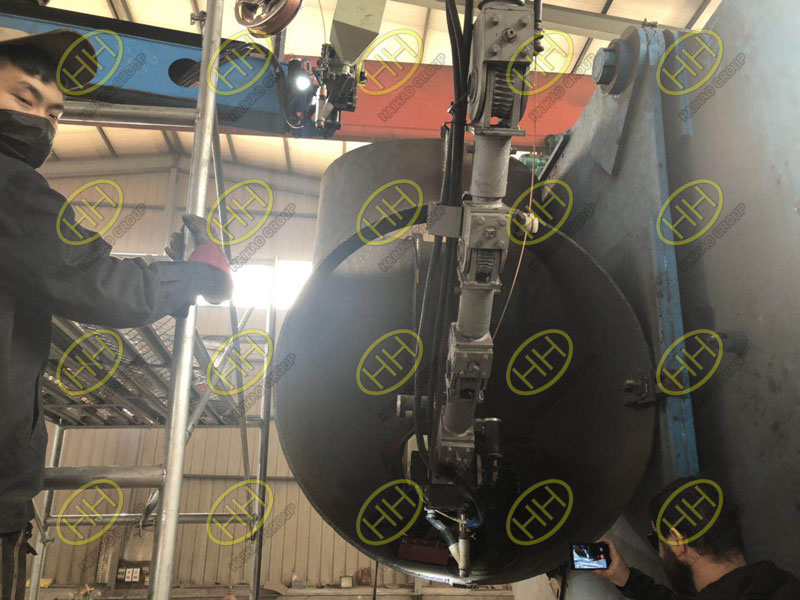

The automatic welding production of large-diameter elbows in Haihao Group

Medium plate welding

The middle plate is used to make half of the elbow section with a press, and then the two sections are welded together. This process is generally used for elbows above DN700.

As a professional supplier of pipe fitting,we have more than 30 years of experience in this industry.If you have any problem,please contact me.