The Brazilian customer customized transition SA-312-304 DN 8″ 22MM SMLS fittings

As a company with over 40 years of expertise in the piping systems industry, Haihao Group has developed strong capabilities in customized manufacturing, a vital aspect of our service offerings. Recently, a Brazilian client approached us with a specific requirement for custom-made pipe fittings based on detailed production drawings. The project involved producing a batch of transition SA-312-304 DN 8″ 22MM SMLS fittings, which presented several challenges that required precise engineering and craftsmanship.

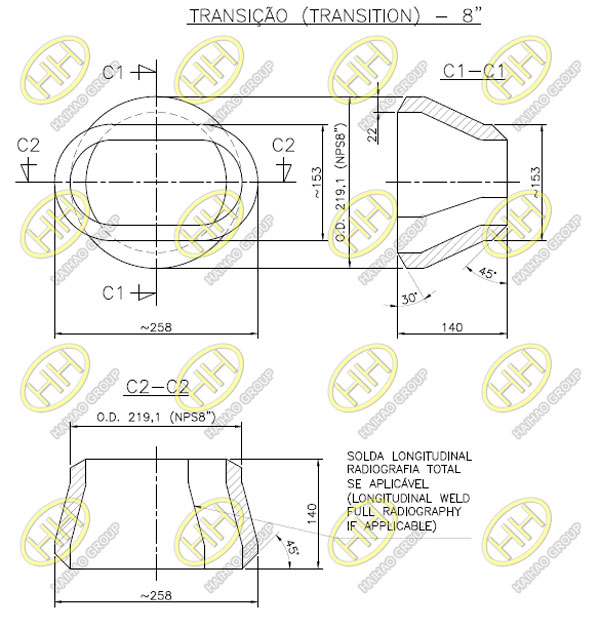

customized transition SA-312-304 22MM SMLS fittings drawing

Overcoming the Challenges of Customization

Custom manufacturing often comes with a unique set of difficulties, and this project was no exception. The DN 8″ 22MM SMLS transition fittings needed to meet strict dimensional and material specifications. The high-precision seamless stainless steel (SA-312-304) pipes, combined with the unique transition requirements, demanded the highest level of technical expertise. Here are some of the key challenges we tackled:

1.Precise Dimensional Control: The client’s design required extremely accurate measurements for both the pipe diameter and wall thickness (22mm). Achieving such precision with seamless stainless steel pipe involves specialized machining and strict quality controls throughout production.

2.Material Characteristics: Stainless steel, particularly SA-312-304, is known for its corrosion resistance and strength, making it ideal for harsh environments. However, working with this material demands advanced techniques in both forming and welding to maintain its integrity without compromising the mechanical properties.

3.Transition Fitting Requirements: The transition feature of the fittings adds complexity to the production process, as it involves connecting pipes of different diameters or thicknesses. Our engineers developed a custom solution to ensure seamless transitions without creating weak points or areas prone to corrosion.

4.ABS Certification: To further guarantee product quality and safety, these fittings were subjected to ABS certification. This required the products to undergo stringent testing and inspection, ensuring they meet international standards for use in marine and offshore environments.

Packaging and Delivery

Given the high value and custom nature of these products, wooden box packaging was selected to ensure safe and secure delivery. This type of packaging provides extra protection during transport, safeguarding the fittings against any potential damage while maintaining their quality from our factory to the client’s location.

Haihao Group’s Customization Strength

This project is another testament to Haihao Group’s ability to handle complex, custom manufacturing challenges. With decades of experience in the piping systems industry, we have built a robust infrastructure and team of experts capable of delivering tailor-made solutions to meet the specific needs of our global clients. Our advanced production capabilities, combined with a commitment to quality and precision, enable us to deliver products that not only meet but exceed customer expectations.

As always, Haihao Group is proud to support our clients with bespoke solutions, ensuring that every product we manufacture is of the highest quality, backed by global certifications and our unwavering dedication to excellence.