Haihao Group delivers customized nozzle AY products for Russian client

At Haihao Group, we pride ourselves on our ability to meet the diverse and specialized needs of our global clients. Recently, we successfully fulfilled an order for a Russian client, supplying a range of piping system products. Among these were custom-manufactured Nozzle AY components, made from ASTM A333 Gr 6 and ASTM A312 GR.TP304/304L materials. This order exemplifies our capability to produce high-quality products precisely according to client specifications and drawings.

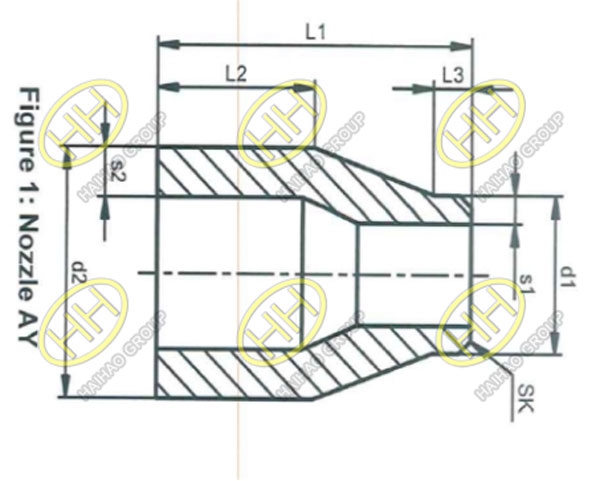

Customized Nozzle AY Products Drawing

Product Specifications

Product: Nozzle AY

Materials: ASTM A333 Gr 6, ASTM A312 GR.TP304/304L

ASTM A333 Gr 6 is known for its excellent toughness and low-temperature performance, making it ideal for applications in colder climates or where low-temperature service is critical.

ASTM A312 GR.TP304/304L is a highly versatile stainless steel grade, offering excellent corrosion resistance, ease of fabrication, and high strength, making it suitable for a variety of industrial applications.

Client Collaboration

The Russian client provided detailed drawings for the Nozzle AY components, specifying precise dimensions and material requirements. Our engineering and production teams collaborated closely with the client to ensure every aspect of the design was meticulously followed. This collaborative approach ensured that the final products met the client’s stringent quality standards and functional requirements.

Manufacturing Excellence

At Haihao Group, we leverage advanced manufacturing technologies and strict quality control processes to produce piping system components that meet international standards. For the Nozzle AY components, we utilized state-of-the-art machinery and experienced technicians to ensure precision and consistency in every piece.

Customized Nozzle AY Products

Manufacturing Steps:

Material Selection: Carefully selecting ASTM A333 Gr 6 and ASTM A312 GR.TP304/304L materials to match the client’s requirements.

Precision Cutting and Shaping: Utilizing advanced cutting and shaping equipment to achieve the exact dimensions specified in the client’s drawings.

Welding and Assembly: Employing skilled welders to assemble the components, ensuring robust and reliable joints.

Quality Inspection: Conducting rigorous inspections at each stage of production to ensure the highest quality standards are met.

Final Testing: Performing comprehensive tests to verify the functionality and performance of the Nozzle AY components under various conditions.

Client Benefits

By choosing Haihao Group, our Russian client benefited from:

Customization: Products manufactured precisely according to their specifications and drawings.

Quality Assurance: Adherence to strict quality control measures ensuring reliable and durable products.

Timely Delivery: Efficient production and logistics processes to ensure timely delivery of the order.

Technical Support: Ongoing technical support and consultation to address any queries or requirements.

Haihao Group is committed to providing high-quality, customized piping system products that meet the specific needs of our clients. The successful delivery of the Nozzle AY components for our Russian client is a testament to our manufacturing expertise and dedication to customer satisfaction. We look forward to continuing to serve clients worldwide with our superior products and services.

For more information about our products and capabilities, please visit our website or contact our sales team. We are here to help you find the perfect solutions for your industrial needs.