Annealing process in the pipeline

Annealing is one of heat treatment for metal,which heat the metal into a certain temperature,maintain enough time,then cool at suitable speed,in order to reduce hardness,improve maching features,eliminate remaining stress.Exactly specking,annealing is a heat treatment for materials,including metal and nonmetal.

In pipeline production,annealing is widely used.There are some process standards of annealing,such as full anneal,process annealing,short cycle anneal,weld annealing etc.

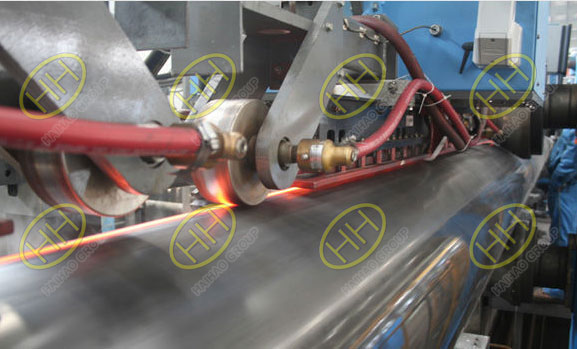

Weld Annealing Equipment in Haihao Group

The high temperature of annealing may result in oxidation of the metal’s surface,resulting in mill scale.If mill scale must be avoided,annealing is carried out in a special atmosphere,such as with endothermic gas (a mixture of carbon monoxide,hydrogen gas,and nitrogen gas).Annealing is also done in forming gas,a mixture of hydrogen and nitrogen.But there is one problem,the color after annealing without oxygen is unstable.