Haihao Group Supplies 56” WPL6 Long Radius 90° Pipe Elbows for Sour Service to Kazakhstan

Haihao Group has successfully completed the fabrication and shipment of 56-inch ASTM A420 WPL6 long radius 90-degree butt-weld elbows for a major energy project in Kazakhstan.

These elbows are engineered for sour service applications, requiring stringent material control, enhanced toughness, and resistance to hydrogen-induced cracking.

Designed and manufactured in accordance with ASME B16.9, the elbows meet all requirements of the client’s low-temperature and sour-environment pipeline system.

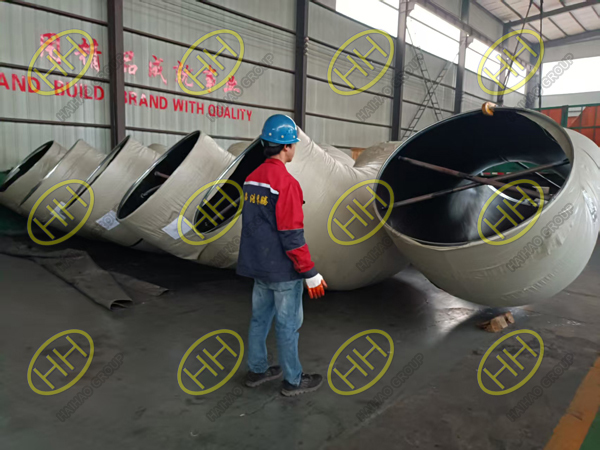

56 inch WPL6 long radius 90° elbow ready for shipment

Project Product Overview

| Item | Specification |

|---|---|

| Product | Butt-weld long-radius elbows |

| Size | 56 inches |

| Angle | 90° |

| Type | Long Radius (LR) |

| Material | ASTM A420 WPL6 (Low-Temp Carbon Steel) |

| Design Spec | ASME B16.9 |

| Wall Thickness | 9.53 mm |

| Manufacturing Requirements | PWHT, double-welded, no mitre welds |

| Service Condition | Sour service |

| Chemical Control | Ultra-low S & P — Sulfur ≤ 0.002% |

| Testing | MTC, HIC test, coupon left in furnace for HIC inspection |

These elbows were custom-manufactured to meet the client’s sour-service environment, where both mechanical integrity and resistance to hydrogen damage are essential.

Strict Manufacturing and Heat Treatment Requirements

1. Double-Welded Construction Without Mitre Welds

The elbows are produced using a double-welded process, ensuring full penetration and uniform strength.

Per the client’s request, no mitre or segmented welds were allowed, guaranteeing higher integrity for high-pressure sour media.

2. PWHT (Post-Weld Heat Treatment)

All elbows underwent post-weld heat treatment to:

- Reduce residual stresses

- Improve toughness at low temperatures

- Enhance stability under sour service conditions

PWHT is essential for WPL6 fittings used in hydrogen sulfide–containing environments.

Material Chemistry: Ultra-Low Sulfur and Phosphorus

For sour service conditions, material cleanliness is critical.

Haihao Group controlled the steel chemistry to achieve:

- Sulfur ≤ 0.002%

- Phosphorus within strict limits

Low sulfur significantly improves resistance to sulfide stress cracking (SSC) and hydrogen-induced cracking (HIC).

Comprehensive Testing for Sour Service Quality Assurance

To guarantee structural reliability in sour media, Haihao Group performed complete testing and documentation, including:

✔ MTC (Mill Test Certificate)

Provided according to EN 10204 3.1 or client requirement.

✔ HIC Test Report

Hydrogen-Induced Cracking (HIC) testing was conducted using test coupons kept inside the same furnace batch to ensure accurate representation of real production conditions.

✔ Dimensional & Non-Destructive Tests

- Visual Inspection

- UT Examination

- Dimensional Verification per ASME B16.9

Our strict quality control ensures each elbow performs safely and reliably in harsh operating conditions.

Supporting Critical Infrastructure in Kazakhstan

These elbows will be installed in a sour-service pipeline system used in oil and gas processing in Kazakhstan.

Haihao Group’s ability to produce large-diameter WPL6 elbows with PWHT and HIC testing reinforces its role as a trusted global supplier for:

- Oil and gas pipelines

- Refinery piping systems

- Low-temperature processing units

- Sour gas treatment facilities