Haihao Group delivers MSS SP-97 A182 F316 45 degree socket weld latrolet for customers in Singapore

As a comprehensive service provider integrating industry and trade, Haihao Group offers various pipe fitting solutions that meet international standards to global customers. Recently, we delivered a 45-degree socket weld latrolet (A182 F316 material) for an energy project in Singapore. The socket weld latrolet is designed with a special specification of 1″x10″, and the wall thickness is precisely controlled at 23.83mm, meeting the requirements of 3000# high-pressure working conditions. Its structural design strictly follows the dimensional tolerance requirements for socket weld latrolet as stipulated in the MSS SP-97 standard.

MSS SP-97 A182 F316 45 degree socket weld latrolet

Dimensions of 45 degree socket weld latrolet:

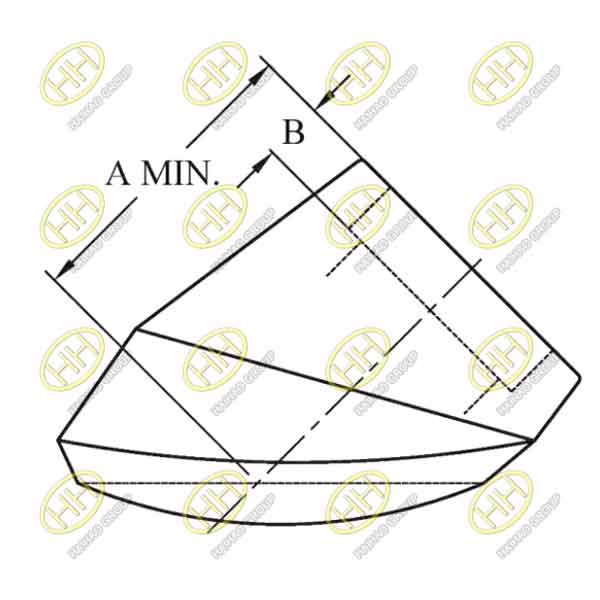

45 degree socket weld latrolet drawing

| Outlet(DN) | B Min.(a) | A(Top of fitting to Run Pipe) | |||

| Class 3000 | Class 6000 | ||||

| A min. | A max. | A min. | A max. | ||

| 8 | 9.5 | 38.1 | 42.9 | 38.9 | 47.6 |

| 10 | 9.5 | 38.1 | 42.9 | 38.9 | 47.6 |

| 15 | 9.5 | 38.1 | 44.5 | 46.0 | 55.6 |

| 20 | 12.5 | 46.0 | 50.8 | 54.0 | 63.5 |

| 25 | 12.5 | 54.0 | 63.5 | 61.1 | 73.0 |

| 32 | 12.5 | 61.1 | 76.2 | 65.1 | 77.8 |

| 40 | 12.5 | 63.5 | 76.2 | 78.6 | 85.7 |

| 50 | 16.0 | 76.2 | 84.1 | 78.6 | 104.8 |

Note: (a) “B” Minimum Socket Depth per ASME B16.11

Quality inspection of MSS SP-97 A182 F316 45 degree socket weld latrolet

During the product realization process, we ensure reliability through a three-stage quality assurance system:

Raw material verification: For the A182 F316 stainless steel material, a double insurance mechanism of spectral analysis and mechanical property re-inspection is implemented to ensure that the material certificate is completely matched with the physical parameters

Process control: The 45-degree socket weld latrolet adopts a combined process of CNC pipe bending and precision machining. The key welding parts undergo 100% penetration testing (PT) + ultrasonic testing (UT).

Finished product verification: In addition to the regular size spot checks, pressure simulation tests were conducted for each socket weld latrolet, and the pressure values were verified by increasing by 15% in accordance with the ASME B16.11 standard.

It is worth emphasizing that this type of MSS SP-97 A182 F316 45-degree socket weld latrolet performs particularly prominently in the low-temperature working conditions of LNG. The engineering team of Haihao Group can provide one-stop services ranging from selection calculation, stress analysis to installation guidance based on the actual needs of customers. We can supply pipe fittings, flanges, steel pipes and various pipe fittings. If you need pipeline products, please feel free to contact us at sales@haihaogroup.com